Sustainability

Sustainability

Water Resource Management

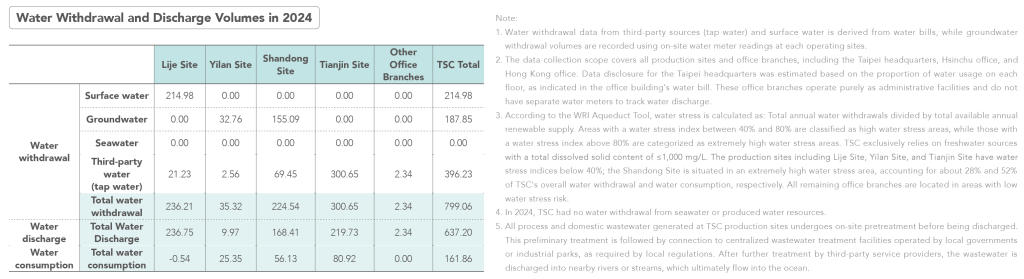

As a semiconductor company, TSC recognizes the operational risks posed by climate change and water scarcity. In response, TSC continues to strengthen water stewardship across all sites by monitoring withdrawal, managing water quality, and maintaining ISO 14001 certification to drive ongoing improvements. Compliance with local water and wastewater regulations remains a key priority.

The Yilan and Lije sites are located in water-stable regions with consistent rainfall and low scarcity risk. The Tianjin site does not rely on groundwater and has experienced no water shortages. The Shandong site, identified as high risk by the WRI Aqueduct Tool, has implemented conservation measures since 2016, including eliminating high-consumption processes, promoting water recirculation, and reducing reliance on groundwater.

Policy and Commitment

- Comply with local water resource management regulations, aiming to improve water use efficiency through monitoring and record-keeping, while progressively strengthening water risk assessment and analysis. For sites with higher risk levels, implement water conservation mechanisms and set specific reduction targets.

- Commit to ensuring that all wastewater discharges comply with local regulations and effluent quality standards.

Management Approach and Evaluation Mechanism

- Regularly evaluate site-specific water risks using the WRI Aqueduct Water Risk Atlas, and apply tailored management measures.

- For sites with medium or higher water risk, implement a comprehensive water stewardship framework, including monitoring of water use, reclaimed water utilization, source diversification, and contingency planning.

- Maintain ISO 14001 Environmental Management System certification at all sites, reinforcing water stewardship through internal audits and external inspections.

- Establish Wastewater Management Procedures and drainage monitoring systems at each site; regularly test water quality parameters and report results to local authorities in compliance with regulations.

Wastewater Monitoring Mechanism

TSC has implemented a comprehensive wastewater management system to reduce environmental impact. Each site operates treatment facilities under permits aligned with local Effluent Standards, conducting daily water quality testing and regular third-party verification to ensure compliance. Standardized Wastewater Management Operating Procedures are followed at all sites, detailing collection, monitoring, testing, and reporting protocols. Discharge and chemical dosage are recorded daily, with 24-hour monitoring in place. Data is reviewed by system engineers and supervisors, and monthly reports are submitted for site-level review.

Some wastewater contains trace amounts of nickel and fluoride. Taiwan sites comply with the Effluent Standards for semiconductor manufacturing; China sites follow the Integrated Wastewater Discharge Standards enforced by local authorities.

Historical Trend of Wastewater Discharge

Discharge volumes vary by site due to differences in production scale and activities. In 2024, TSC discharged a total of 636.91 million liters of wastewater. All sites remained in full compliance with applicable standards, and no water pollution incidents occurred.

© Copyright 2026 Taiwan Semiconductor Co., Ltd.

- Cookie Settings

- Website Feedback

- Privacy Policy

- Terms of use

- Terms & Conditions